Robot Arm End Effector: Zot Effect

Background

Archytas Automation aims to create educational robot kits that could be utilized in a classroom setting for teaching as well as competition; additionally, Archytas is hoping to expand their robot arms into other commercial settings to ease the labor of various tasks. Their gripper end effector is tasked with the ability to grip and move a large range of objects with varying shapes, sizes, and payloads. Current issues with the gripper include the housing of the motor and its wiring, its limiting functionality, and difficulty to assemble.

Robot Arm

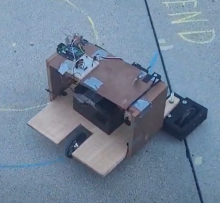

Our team will design, build, and test a robot arm.

A key function of our Robot Arm design is the implementation of a proxy arm to control and program the arms motion. The goal is to create an intuitive user interface that can quickly repurpose the arm for the task at hand.

Our inspiration for this proxy arm is from a youtube video demonstrating the control and programming of a robot arm. In this video a button is pressed to begin recording the proxy arms motion. It can be controlled in real time or the motion recorded for playback. Unfortunately the video has since been made private.

Small Scale Wind Turbine

Our Small Scale Wind Turbine project aims to provide a sustainable and cost-effective solution for individuals, organizations, and communities looking to generate their own electricity. In this project, we focus on designing and building a compact, lightweight, and durable small-scale wind turbine that can generate a minimum of 10 watts of electricity in low wind speed conditions, while being able to withstand wind speeds up to 18 m/s. The wind turbine must fit into a 50cm x 50cm x 50cm box without its mounting assembly and have a total cost of less than $300. The goal is to create a wind turbine that is both efficient and accessible, providing a reliable source of energy for those in need. Through careful design and rigorous testing, our Small Scale Wind Turbine program aims to create a high-quality and cost-effective solution for renewable energy generation.

Autonomous Interface Engineering

Background

"Robot for Executing Physics-Inspired Path Planner" is a capstone design project. The project team will design and build a self-contained and self-sufficient robot capable of tracking a preplanned collision-free path in a 2D environment containing circular obstacles with a maximum error of 10% at any point.

Unique Background of Project Team Members

Helping Hands

Background

This student-led project is a partnership with the LN4 Hand Project. The LN4 is a non-profit organization that aims to provide free prosthetic hands to anyone in need- anywhere in the world. They have already delivered over 5000 of their prosthetic devices to below-the-elbow amputees, mainly in India and Cambodia. There remains an estimated 145,000 eligible patients globally, waiting to receive a helping hand.

High Pressure Quick Disconnect 189 Project

Pressure fed rocket engines make use of high pressure pressurant tanks that should be

topped off after pressing propellant tanks. One of the ways to accomplish this safely is to make

use of a remotely controlled high pressure quick disconnect (QD) system. The system would be

responsible for disconnecting the high pressure pressurant fill line after refilling the pressurant

tank to nominal pressures. By excluding the need to have a manual high pressure disconnect

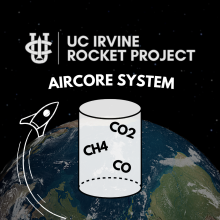

UCI Rocket Project Solids: Aircore Team

UCI Rocket Project Solids Team will be building its first large collective rocket to compete in the 10k Commercial-Off-The-Shelf (COTS) Propulsion Category at the 2023 Spaceport America (SA) Cup. Our team is tasked to design an AirCore Atmospheric Sampling System that will collect and test air samples from different altitudes, allowing the team to compare the data and analyze its differences in gas concentrations. As a team, we aim to combine our interdisciplinary knowledge to meet the system requirements which include: weighing at least 4 kg, being able to withstand 10 Gs of force, be at least 3Us, ground tested, and survive 4 launch attempts. Our group aims to familiarize ourselves with the engineering design process and apply critical thinking to design a fully functional payload system for our rocket.

LAVEP: Lightweight Advanced VTOL EDF Project

Background:

This team is tasked with improving upon the vertical takeoff and landing aircraft prototype Kestrel. Kestrel uses 3 electric ducted fans (EDFs) which are housed inside nacelles which can rotate about the pitch axis such that their thrust can be redirected from being expelled rearward to downward and are powered by lithium polymer batteries. The augmentation of these nacelles allows for standard forward flight, transitional flight, and vertical flight.

FUSION Engineering Project: Team Peter's Anteaters

In this project, we will be creating an autonomous cleaning robot that resembles the form of a Roomba. Upon completion, our cleaning robot will go through a challenging obstacle course where it will need to avoid obstacles while simultaneously vacuuming up dust and debris in the play field. Through this project, we are synthesisizing several disciplines of engineering including mechanical, robotics, electrical and computer engineering in order to accomplish our goal.

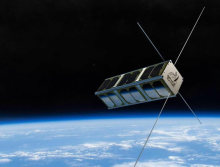

UCI CubeSat

BACKGROUND:

UCI CubeSat is a student-led effort to design, manufacture, and launch a 2U nanosatellite to conduct experiments on a UCI research payload called a variable emissivity device (VED).

These experiments aim to ascertain whether the VED will be viable for use as a cheap, reliable method of thermal management on future spacecraft. UCI's CubeSat, AntSat1, will relay data on performance in various degrees of solar exposure and at varying adjustable emissivity values while in orbit.

OBJECTIVES:

FUSION Engineering Project: Autonomous Vacuum (Team Oompa Loompa Broombas)

The objective of the FUSION Engineering Project is to design and create a functional autonomous vacuum cleaner. Each team must adhere to certain design specifications set by the Project Directors and will compete with each other at FUSIONCon in May 2023. Each team’s goal is to create a cost-effective robot while maintaining functionality.

UCI Rocket Project (Liquids) Pressure Testing Unit (PTU)

The UCI Rocket Project PTU is a project whose goal is to design a pressure testing system that can safely and accurately pressure test components used by the Liquid Rocket Team on their current Preliminary Test Rocket and be adaptable to their next generation rocket. The designed PTU will improve upon UCI Rocket Project's current pressure testing equipment that is difficult to use and requires multiple people to setup. It will be remotely controlled so that the operator is at a safe distance and pressure transducers will provide accurate data. The PTU will be able to test relief valves, calibrate pressure regulating valves, and leak test all components.

FUSION Engineering Project: Autonomous Vacuum (Team swiffer diss track)

Background:

The FUSION Autonomous Vaccum project aims to provide members with the opportunity to work with a diverse range of other engineering majors while aquiring hands-on experience with Arduinos and CAD modeling.Although we share the same objective as the other project teams within FUSION, we will differentiate ourselves with our unique design and approach to problem-solving in order to be a competitive oponent in the end-of-the-year competition.

Goal and Objectives:

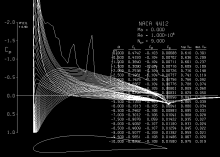

Validation of a Numerical Prediction Method for Aerodynamics

The goal of our project is to test and validate an inexpensive numerical analysis tool for lift and

drag calculations of a 2D airfoil. The project will use the XFOIL code as a prototypical numerical

predictive tool for aerodynamic analysis. An experimental campaign will be designed to provide

reliable data to validate the numerical prediction method. The team will be fully responsible for

coming up with a set of wind tunnel experiments, obtaining the necessary materials, executing

the experiments, and fully documenting methods and results. In addition, the team will need to

master the XFOIL code and execute the necessary calculations.

Small-Scale Wind Turbine Prototype

This project encompasses one of many alternative solutions to a transition into clean and renewable energy sources. Wind turbines, when designed and constructed properly, can yield and store a substantial amount of electricity all from wind energy. To keep up with the high power demands of local electrical grids, most modern day turbines need to be immensely large in size, sometimes up to 500 ft tall, in order to generate enough electricity. Recently, more thought is being put into harnessing the efficiency of traditional turbines but on a smaller scale to satify more domestic electrical needs. The Small-Scale Wind Turbine projects here at UCI is involved with Collegiate Wind Competition and focuses on this small scale optomization of modern day giants.

Steerable Mechanical Walker: Gonk Walker

For the Winter 2023 quarter, the Steerable Mechanical Walker project focuses on creating a robot that can move and turn without human interaction. This iteration of the walker will use four legs which will allow for movement around its environment. This version of the walker is inspired by the GNK power droids from the Star Wars franchise. The design of the mechanical walker will have a Gonk droid theme which will give it "personality". The ultimate goal of the Gonk Walker is to be capable of steering autonomously in preparation for the day it is tested against the MAE 106 robots.

FUSION Engineering Project: Autonomous Vacuum (Team Wall-Is)

FUSION's Engineering Project provide students with the opportunity to design and manufacture a robot from scratch and learn the basics of automated controls, motions/distance sensors, and programming.

The goal is to design and manufacture an autonomous robot capable of picking up small amounts of dirt and debris from the ground simultaneously avoiding any obstacles in the way.

Competition:

Each team will begin with their robot in a square 5 by 5 feet field with small pieces of dirt and obstacles randomly scattered around. The objective for the robot is to pick up the pieces of dirt while simultaneously avoiding the obstacles present in the way. Each team will be scored based on their performance during the 2 minute period. Each piece of ‘dirt’ picked up by the robot is +1 point and each time the robot hits an obstacle is -1 point. The final score in the end will represent the team’s score and will be used to determine the winner.

CONCEPT VTOL

Background

Due to COVID-19, the medical industry has received an increase in demand for rapid covid tests, as well a need for contactless interactions between humans. The increase in traffic for hospital visits has strained the current logistics network and increased delivery times. CONCEPT VTOL plans to mitigate the risk for contamination and decrease delivery times by designing a novel VTOL drone that will deliver prescriptions and rapid covid tests from the UCI Student Health Center to UCI students within a 5-mile radius.

UC Irvine Solar Airplane

We are a group of UCI engineering students with the goal to design, build, and fly a solar-assisted aircraft. Our project's aim is twofold: to prove the viability of solar power in airplanes/drones, and create a device that can assist in humanitarian aid missions caused by climate change.

UCI Spacecraft Thermal Management Systems

Research Mission: The goal of Spacecraft Thermal Management Systems (STMS) is to be developing several Variable Emissivity Device prototypes, or VEDs, one of which is to be applied as payload to a CubeSat and launched into Low-Earth Orbit. This VED will mitigate thermal loads from the sun and internal satellite electronics and offers a low-cost thermal control solution to absorb or reject heat from spacecraft. We work closely with the UCI CubeSat project to coordinate the VED and satellite operations.

Portable Shoulder Exercise Device

We are a team of undergraduate Engineering students that are working towards the common goal of improving people's quality of life. Our team's objective is to design and build a portable shoulder exercise device that is capable of rehabilitating the patient's shoulder muscle. Ultimately, we want the patients to be able to perform tasks that require overhead movement and extension of the elbow. Our device will be used by patients and physical therapists at the UCI Medical Center. We hope our device aids the needs of those with impaired shoulders and potentially improves the healing process and the long-term mobility of their arms.

UCI CubeSat - Antenna Deployment Mechanism

This project aims to create a compact, lightweight, and highly reliable antenna deployment mechanism that will be attached to an Orbital 2U CubeSat satellite. It must survive launch and orbital conditions and allow data to be relayed from the CubeSat to the ground station at UCI. We must ensure that we design a working mechanism that fits within the limited space provided to us on the 2U CubeSat. The antenna has to be the correct length for the material used to provide the needed frequency. We work alongside UC Irvine’s Cubesat team to verify design requirements and ensure that our designed mechanism will be compatible with the team’s CubeSat which will be launched onboard a third-party launch provider when complete.

Robot for Executing Physics Inspired Path Planned

According to many route planning methods in the available literature, the Robot that we are going to create will follow the path precisely while avoiding probable obstacles. We must discover strategies for finite-dimensional optimizations, in which the ideal path is formed by discrete optimal points. Using the calculus of variations, the Path Follower we will create directly builds the perfect path with the fewest steps. Additionally, it will be able to implement the essential control inputs that the pathfinder scheme specifies. As a proof of concept, an obstacle-oriented map of the environment is first constructed in this offline phase. Control inputs are then transmitted to the robot so that the Path Follower can carry out the command precisely.

Rocket Project Liquid CO2 Ejection System

The purpose of this project is to give the UCI Rocket Project Team a new consistent CO2 Ejection System for the recovery of the rocket that will be used for the Preliminary Test Rocket (PTR). Students will be able to manufacture and develop the system “in-house” and can easily be manufactured to align with the project guidelines. From past designs of the recovery systems and the familiarity of the current rocket, students will be able to pursue more knowledge among higher altitudes with a CO2 Ejection Systems and implement more efficient and cleaner solutions to initiate the recovery process. With ongoing experimentations, students have the opportunity to integrate and improve their knowledge from the future systems of CO2 Ejection to reach higher altitudes in the near future.

Steerable Mechanical Walker

The goal of the Fall 2022 Steerable Mechanical Walker project is to design and build a walking machine with an advanced leg system, a single drive motor for movement, and a single servo motor for steering. The design will be remotely controlled, and should allow the walker to move 1.5 ft/s and follow a circle of 6ft diameter. The team has to provide digital and physical models of two prototypes with test data and demonstration videos with it.