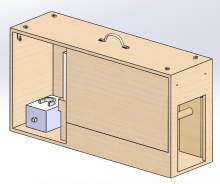

As indicated by the title “Design, Build, Fly”, this project involves the design of an aircraft for the purpose of completing three air missions and one ground mission, building components of the aircraft that are not commercially available, and testing and flying the aircraft. The design of the aircraft is optimized solely to complete the missions. The missions are as follows: For mission 1 (deployment flight), the aircraft must complete 3 laps within a 5 minute flight window without a payload and complete a successful landing; For mission 2 (Staging Flight), the aircraft must complete 3 laps within a 5 minute flight window with a payload of at least 10 syringes; For mission 3 (Vaccine Delivery Flight), the aircraft has 10 minutes to complete as many ‘vaccine package’ deployments as possible; Finally, ground mission is a timed mission with the aircraft in the flight configuration in the “mission box” with Mission 2 and 3 payloads. The assembly crew must demonstrate the functionality of the aircraft by deploying all payloads. The design of the aircraft will focus on the requirements of the third mission where the aircraft must be able to complete a flight course within a time window while carrying a payload and making several takeoffs and landings. The wings, fuselage, empennage, will be drawn and built by the team. Components such as the battery, propellers, motors, wheels will be carefully selected to meet the aircraft performance requirements. The team is divided into sub teams that focus on aircraft performance, propulsion, CAD, payload and the like.