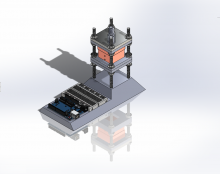

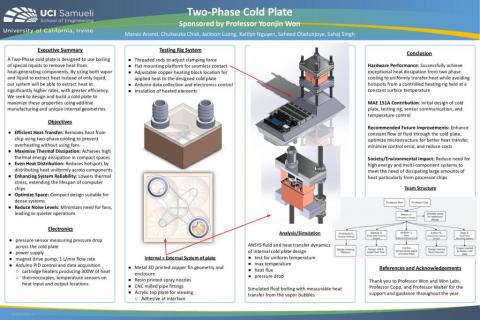

Innovative Cold Plate

Background

The rapid growing field of AI and high-performance computing has led to small-form factor chips (CPUs/TPUs) with exceedingly high heat fluxes. Traditional air cooling struggles to dissipate these thermal loads efficiently. The research from our team at UC Irvine proposes an innovative liquid-vapor phase change cooling plate to address the need for high-performance cold plates that integrate seamlessly with new generation server hardware.

Goal and Objectives

The team seeks to accomplish the following:

Q1 2025 (first half of winter quarter): Market research on industry chip cooling tech and academic literature on heat transfer fundamentals

Q2 2025 (second half of winter quarter): Finalize a design matrix via trade studies, providing complete design proposals for internal/external components, testing/data collection, and ANSYS fluid simulations

Q3 2025 (first half spring quarter): Validate manufacturing process and achieve target metrics in prototype testing

Q4 2025 (second half spring quarter): Revise design, scale for certain server motherboards and optimize for cost and performance

Design considerations

Latent Heat Absorption: Phase change transports 100-1000x more heat per unit mass than the sensible heating in single-phase

Vapor Bubble Dynamics: If nucleation can be attained, smaller bubbles detach faster, and would enhance heat transfer (Risks: avoid critical heat flux and dry out with unique surface design)

Engineered Microstructures: Increase surface area, reduce pressure drop, and improve passive pumping through capillary action. Our structures consider those factors and seek to decouple liquid inflow and vapor escape.

Jet Impingement: micro-jets to introduce fluid into the cooling plate would target hotspots in TPUs and provide a uniform temperature across the chip.

Dielectric Coolants and Material Coatings: Novec 7100 (3M) and certain materials enhance thermal conductivity and other measurable performance elements.

Performance Targets

Max Heat Flux: 600 W/cm^2

Max Temperature: < 70 deg Celsius

Temperature Variation: < 3 deg Celsius

Pressure Drop: < 80 kPa

Thermal Resistance: < 0.03 Celsius/W

Cost per unit: <$100

Documentation

https://drive.google.com/drive/folders/1rOgAc_xijDI5-TOCv5kV7sPx3KINNvwk?usp=sharing

External Website

https://coldplayt.godaddysites.com/

Team Contacts

Team Lead: Manav Anand (manand2@uci.edu)

Jackson Luong (jacksol4@uci.edu)

Sage Singh (sahajs@uci.edu)

Saheed Oladunjoye (soladunj@uci.edu)

Chukwuka Chidi (cchidi@uci.edu)

Sponsor/Advisor

Professor Yoonjin Won