Solar Airplane

Background

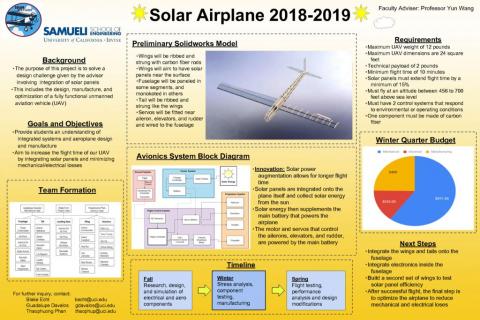

The purpose of this project is to provide a context for its members to design and manufacture an airplane that must somehow integrate solar panels into it. The design challenge is set by the client (in this case, the project advisor) and reviewed by the project lead. The team then narrows down a design, manufactures a prototype, and tries to optimize the design throughout the year.

Design Challenge: A design to extend the flight time of a UAV that includes the integration of solar panels for the purpose of disaster relief.

When a natural disaster strikes it can be very difficult to gauge the scope of damage. Often times satellite imagery is used to help show the extent however this is not as readily available and satellite revisit times are still not fast enough. This imagery can be used for a plethora of uses such as evacuation planning, rescue operations and monitoring repairs of areas. A small scale drone can help fill in for the satellites. A drone is more accessible by organizations and is capable of performing small imaging collection taskings. The drone can be flown at low heights to achieve a very low ground sample distance as well. The design challenge assumes the operators of the UAV will be operating remotely and have flying experience. The operators will not be required to know any of the engineering concepts, but should be able to easily fix parts via manual and template manufacturing methods (for example laser printing, molding, anything with a template). The drone should be portable and fit within a standard truck bed used by service workers. In flight data should be given via remote terminal.

Goal and Objectives

Overall goal: The Solar Airplane Project Team will seek to design, manufacture, and test a UAV in order to educate its members on the engineering design process in the field of aircraft design and integrated systems design. It will accomplish this by approaching a design challenge assigned by the acting adviser and reviewed by the project lead that involves the design and manufacture of an aircraft and the integration of solar panels.

- This project aims to extend the flight time of an airplane by mitigating the mechanical and electrical losses and augmenting the battery using solar panels as a proposed solution to the design challenge.

- The plane will be designed and manufactured by the team members to reduce mechanical and physical losses as well as take advantage of the renewable energy source solar panels provide.

- The design should be modular and convenient to assist those in hazardous areas reduce the risk to their lives while still managing to save the lives of others.

- The operation of the design should not require any more training than necessary to fly a standard hobby plane

- A collection of documents that details the entirety of the engineering process as the team proceeded through it will be collected from each team and compiled into a single organized document to provide context and data for next year's (or later) team

.

Quarterly Progress

Fall Quarter:

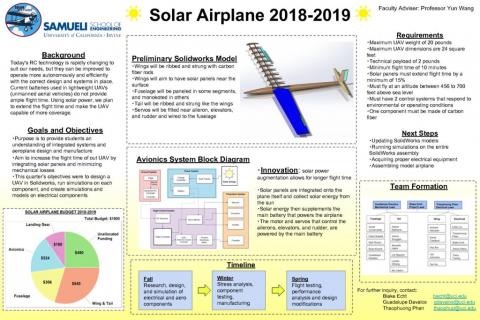

Fall quarter consisted primarily of the design phase of the project. Teams were formed through initial research tasks, such that individuals could gain a feel of who they could work well with. The team then divided into several subteams: Electrical (Now renamed Avionics), Fuselage, Tail, and Wing teams. Each team, approximately with 6 members, would then carry out weekly tasks beginning with concept generation, relevent analytical equations, and case studies where they would compile a list of relevent design solutions that could accomplish the task. Through the use of numerical solutions, analytical paramters, and research, an initial design had been created and modeled by the end of the quarter.

Winter Quarter:

A plan of manufacture has been created by each of the subteams to gain a sense of supplies necessary as well as training. Each team then began to redesign based on manufacture and finalising any dimensions they had missed in the Fall quarter. Most teams opted to use balsa wood that would be laser printed. Aside from this, the Avionics team began to test all the electrical equipment and benchmark their inputs and outputs. The most important of these electrical systems is the flight controller, the pixhawk 2. This model of pixhawk is only a few years older but not at all obsolete. The Avionics team had finished the benchmarking around week 7, while all the hardware for the other three teams had arrived around the same week. By week 9, most teams had finished the manufacture and assembly of their respective section. By week 10, all teams will be ready to begin integration. Aside from this, a fifth team had been created week 8, the Landing Gear team. This team is primarily composed of MAE 193 students, who will carry their week work into the Spring Quarter

Spring Quarter:

We are hoping to continue the integration and have our first test flight by week 3. We are currently on track for this.

*Will update as the quarter progresses*.

Contacts

Faculty Advisor(s):

Yun Wang - yunw@uci.edu

Student Contact(s):

Saingyou Eung - seung@uci.edu