Red Hot Routers: CNC Hot Wire Foam Cutter

Background

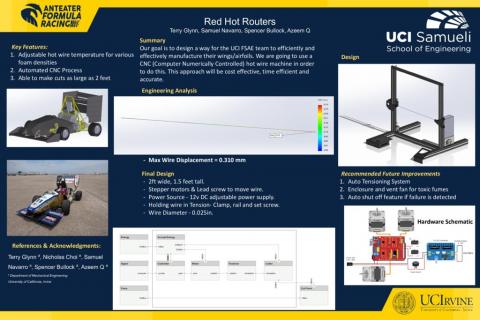

By orienting air foils in a unique manner, downward forces can be generated on a car, providing it with the ability to increase its cornering speeds due to enhanced grip, improving its overall performance. The aerodynamics sub-team of Anteater Formula Racing (AFR) will use the foam airfoils as a base to layer composite materials on top to create a final design.

Goals and Objectives

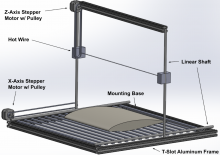

- Design and produce a precise CNC hot wire foam cutter able to cut pieces of foam 2 feet long

- The entire project should be completed with a maximum cost of $400

- The system should be user friendly and time efficient

Week 7: Design Phase Iteration 1- Determine XZ axis stepper motor system, hot wire system, and user interface

Week 8: Design Phase Iteration 2- Finalize decisions made in week 7, determine mounting base and overall structure

Week 9: Complete a trade study to ensure success of our design, majority of parts are ordered, BOM is developed, master CAD is complete

Week 10: Animated CAD complete, technical documentation complete

Target User

Anteater Formula Racing, specifically the Aerodynamics sub-team. They will use the CNC machine to create custom airfoils to be used on the UC Irvine FSAE Car. Airfoils are used for the design of the front splitter and rear wing, do help generate downforce, allowing for greater speeds on turns. This results in decreased lap times and a competetive edge.

Team Contacts

Spencer Bullock: bullocks@uci.edu

Samuel Navarro: sjnavar1@uci.edu

Terry Glynn: fglynn@uci.edu

Azeem Qureshi: arquresh@uci.edu

Sponsor/Adviser

Nicholas Choi: nmchoi@uci.edu