MAE188: Alcon Automation Project

Background

Alcon is a medical devices company sponsoring this project and they have tasked the UCI team with automating the assembly of three separate components. Each system uses a Universal Robot (UR) that is designed to assist in automation. This quarter, the team broke into three sub-teams that are focused on optimizing one system each.

Objective

Currently, Alcon has two problems they would like to solve: slow assembly times and workers experiencing repetitive stress injuries. To overcome these two issues, each automation system is designed to reduce stress injuries and improve manufacturing times.

Speaker: Create a system capable of assembling a multistage speaker box. Primary goal is to improve assembly times.

Manifold: Create a system capable of torquing in plugs to 36 in-lb. Primary goal is to remove repeated stress on technicians.

Packaging: Create system capable of assembling laser probe packages in a clean room. Primary goal is to reduce need for technicians in clean room.

Requirements

- Use URs to automate assembly process

- System must be safe, accurate, and repeatable

- Build, program, and test by the end of the quarter

--

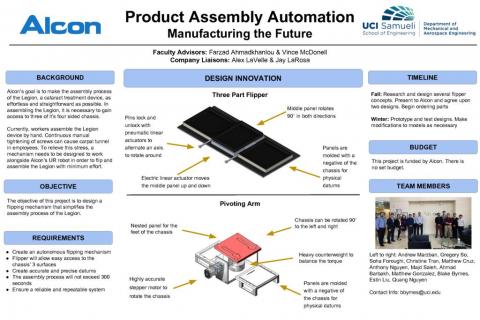

Speaker Assembly

OVERVIEW: The system is capable of completing 5 speaker assemblies per batch. The system requires 2 stages to fully assemble the speaker, those being position 1 and position 2. The speciality fixture uses an interference fit to hold the speaker and is capable of rotating around an axis. The design reduces the number of moving parts allowing for a more reliable and safe assembly.

FEATURES: The elegant design provides the safest and most accurate assembling process. This allows the system to be quickly implemented on the assembly floor.

Manifold Assembly

OVERVIEW: The system is capable of completing 6 manifold assemblies per batch. The assembly utilizes a programmable screw drive, custom plug presenter, and clamping fixture. This design completely eliminates repeated stress injuries for technicians.

FEATURES: The plug presenter is custom designed to work with the UR. The locking clamp fixture is capable of quickly and easily securing the manifold.

Packaging Assembly

OVERVIEW: The system is capable of packaging 60 trays in a single batch. The material flow is designed to allow the UR to pick up the laser trays with a pneumatic actuator and then place them into a laminator. The system removes all human interaction after the trays are loaded.

FEATURES: The material flow system is designed to be as safe and reliable as possible. The end effector is designed to pick up the trays and sealing paper using compressed air for suction. The hook in the back allows the UR10 to pull/push the material flow drawers.

--

Faculty Advisors: Professors Farzad Ahmadkhanlou & Vince McDonell

Company Liaisons: Alex LaVelle & Jay LaRosa

Team Members: Jiayu Wu, Jake Pan, Andrew Marzban, Estin Liu, Blake Byrnes, Quang Nguyen, Matthew Cruz, Michael Chavez, Matthew Gonzalez, Christine Tran, Adrienne Lee, Majd Saleh

For more information, please contact Blake Byrnes (bbyrnes@uci.edu).