Small Scale Wind Turbine

Background

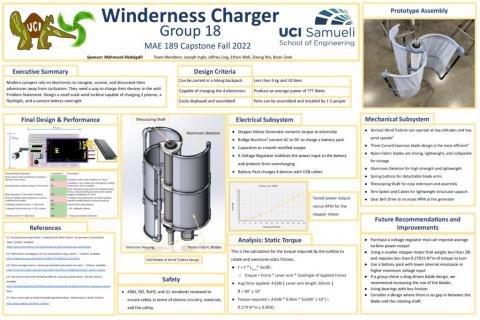

Electronics are universal in our modern society and have been integrated into our everyday lives. Even while camping in the wilderness, people are reliant on their electronic devices like smartphones, flashlights, and cameras. However, all these devices require battery power to function far away from civilization. Thus, our portable wind turbine is the perfect way to recharge these electronics overnight at the campsite.

Miniature wind turbines can harness the energy of the winds in forests and hiking trails into a replenishable supply of electricity. Our vertical wind turbine is an environmentally friendly and convenient source of energy for a wide variety of electronics capable of operating at low wind speeds and being carried in a backpack.

Goals and Objectives

Our team has undertaken the task of designing and prototyping a small-scale wind turbine that can be assebled on site and charge multiple electronic devices overnight. More specifically, the wind turbine needs to be easily assembled and dismantled by one or two people and needs to output enough energy to recharge two cell-phones, a flashlight, a camera battery charger, and a backup power bank. We have been allotted a generous budget of $750 for the purchase of materials and equipment necessary for the development and construction of our wind turbine. We strive to complete our tasks each week and stay on schedule for developing a functional prototype by the end of this quarter.

- Week 1-2: Team Orginization and Design Parameters

- Week 3: Finalize Design Decisions

- Week 4: Finalize Circuitry and Compile Bill of Materials

- Week 5: Testing Components and Circuitry

- Week 6-7: Prototyping and Testing

- Week 8: Prototype Verification and Documentation

- Week 9: Design Recommendations and Conclusions

- Week 10-11: Final Presentation and Report

Mechanical Design Decisions

We researched the benefits and disadvantages of horizontal and vertical wind turbines and decided on a vertical design for the ability to employ omnidirectional winds and capability of operating close to the ground. We chose curved savonius blade shapes for their simplicity of assembly and easy packaging. Nylon fabric was chosen for the blades for its toughness and lightness while also circumventing the difficulty of machining alternative materials into blades. Complimenting the use of nylon fabric, a possible option is to use rods of a strong material to support the shape of the fabric. A "rod and fabric" design is common among successful existing solutions beause of its ability to be both lightweight and compactable. An example would be to use carbon fiber rods as a skeleton.

Electrical Design Decisions

We are using a motor generator to transform torque from the wind turbine rotation into electrical energy. A bridge rectifier will be constructed to convert the AC current output from the generator into DC current that can charge the battery charger pack. The charging station will receive an input current from a USB connection and have more than five USB charging ports to charge all devices simulaneously and regulate output voltage.

Team Contacts

Ethan Woll ewoll@uci.edu

Zikang Wu zikangw1@uci.edu

Jeffrey Ling lingjr@uci.edu

Joseph Ingle jingle@uci.edu

Brian Zeek bzeek@uci.edu

Sponsor/Advisor

Mahmoud Abdelgalil maabdelg@uci.edu