Design Build Fly

Background

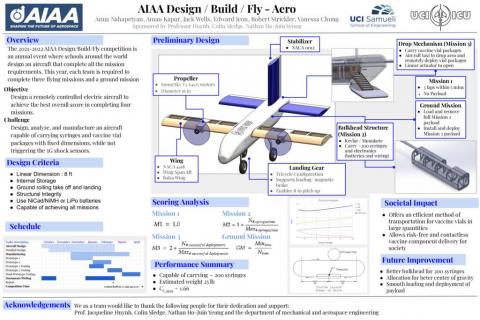

Design, Build, Fly is an annual competition hosted by the American Institute of Aeronautics and Astronautics (AIAA). Every year there are a new set of rules published by the AIAA for the DBF competition. The 2022 competition mission is to design, build, and test a vaccine delivery aircraft that meets each of the 3 mission profiles. The competition will take place in person on the 21st-24th of April 2022 in Wichita, Kansas.

Goal and Objectives

The objective of this year is to build an electric powered, remotely controlled aircraft that is capable of carrying syringes and vaccine vial packages with fixed dimensions, and deploying the packages without triggering the 5G shock sensor on each dimension.

For the year 2021-2022, there are three flight missions and one ground mission:

- Flight Mission 1: Deployment Flight

The aircraft must complete three laps within a 5 minute flight window for this mission. There is no payload required for this mission.

- Flight Mission 2: Staging Flight

The aircraft must complete three laps as fast as it can within a 5 minute flight window for this mission. However, the aircraft must carry the payload, which are syringes and a minimum of ten syringes is required.

- Flight Mission 3: Vaccine Delivery Flight

The aircraft is required to carry vaccine vial packages as its payload and must fly the standard mission profile for each lap. However, the aircraft is required to land anywhere on the runway and taxi to the designated vaccine vial package drop area. The aircraft must repeat the procedure until all vaccine vial packages have been delivered to the designated destination (minimum 1 vaccine vial package is required to be delivered) within a 10 minute flight window.

- Ground Mission: Operational Demonstration

This is a timed mission for the ground demonstration of flight mission 2 and flight mission 3. A crew member from the team will start from a start/finish line, load the full mission 2 payload, and will go behind the start/finish line. Then, the crew member will start again to remove the mission 2 payload and install the mission 3 payload, while finally coming back to the start/finish line.

Ultimately, the goal is to design and build an aircraft that will complete all mission requirements and earn the best overall score by finding the best scoring combinations of the missions.

For more information on the DBF competition for the year 2021-2022, you can visit https://www.aiaa.org/dbf.

Team Name

Our team name is ‘Anteater Flight Club,’ since we are working on the ‘Design, Build, Fly’ team and our primary focus is on the aero part of the project directly correlated with the flight aspect.

Current Progress

During the fall quarter, 2021, we finished our preliminary design of our aircraft including the fuselage, wings, tails, and landing gears. We also focused our conceptual design of the aircraft based on the scoring analysis, which led us to decide a particular mission to focus our design upon. Along with the design, we made plans for prototyping/manufacturing and testing, which we are conducting in the current quarter, Winter 2022.

Manufacturing Plan

The team aims to construct two prototype aircrafts and one final competition aircraft.

- The wings and tails will be manufactured using carbon-composite tubes, 3-D printed components, and balsa wood. The internal wood structural members will be laser cut and assembled using wing jigs and tooling to ensure accuracy.

- The wing and tail spars will likely be carbon-composite tubes but may also be built-up from wooden spar caps and carbon-composite rods. The main structure of the aircraft will consist of a composite tube to which all main components are built around.

- The fuselage fairing will likely be made from a combination of sheeted and covered balsa, and molded lightweight composite parts.

- To minimize weight, vaccine vial packages will likely be machined out of wood to secure both the package and 5G shock sensors in their appropriate directions.

Testing Plan

The goal of testing is to validate assumptions and choices made during design, and to use test results to make more educated decisions in subsequent prototypes.

- Structural tests will validate the design and structural strength of the separate wings, tails, landing gears, and fuselage.

- The propulsion tests will be performed to test the thrust which can be provided and the endurance of work time to validate the assumption and ensure flight safety.

- Control system tests will ensure that all the operation control system and electronic components are operating properly.

- Ground tests will examine the function of the deploy system and practice the procedure of the conversion process between each mission.

- Flight tests will measure various parameters of the aircraft including the minimum distance of taking off, maximum speed, minimum turn radius, endurance, and range.

Team Contacts

- Vanessa Chung - occhung@uci.edu

- Aman Kapur - akapur1@uci.edu

- Edward Jeon - esjeon@uci.edu

- Anna Nahapetyan - nahapeta@uci.edu

- Robert Strickler - stricklr@uci.edu

- Jack Wells - jrwells@uci.edu

Sponsor/Advisor

- Professor Jacqueline Huynh (huynhlj@uci.edu)